- Introduction

- Original M-Sand Vs Duplicates

- M-Sand Vs Crusher Dust

- River Sand Vs M-Sand

Comparison

The natural river sand was the cheapest resources of sand. However the excessive mining of rive bed to meet the increasing demand for sand in construction industry has lead to the ecological imbalance in the state. Now the sand available in the riverbed is very coarse and contains very high percentage of silt and clay. The silt and the clay presence in the sand reduce the strength of the concrete and holds dampness. The natural river sand is the product of sedimentation. mica, coal, fossils and other organic impurities are present in the river sand above certain percentage which make the sand useless for concrete work.

Acute shortage and high price for river sand has lead to the adulteration of sand with salty sea sand which has raised serious concern among builders.

Comparison between Original M-Sand and duplicates

Crusher dust is a byproduct generated while producing crushed aggregates. In wet conditions the crusher dust resembles MSand. The crusher dust does not have a standardised process and do not undergo the basic process of shaping, grading and cleaning.

Original MSand is manufactured through the process of shaping cubically, grading and cleaning.

Cubical shape - Every tiny sand particle of Original MSand is cubical shaped using VSI machine. This makes bonding very strong. State-of-the-art technology helps to control the flakiness and elongation of every sand particle.

The surface of duplicate sand particles are sharp, elongated and flaky, which makes the bonding weak. This deteriorates the strength and durability of concrete.

High quality mix - The mix of Original MSand is perfect because grading is done by double sieve technology adhering to IS 383 (1970) zone l II. Original MSand has microfines of minus 150 microns less than 10% and minus 45 microns less than 2%. This ensures long life and high strength for concrete made of Original MSand.

| IS Filter Grading* |

IS 383 (1970) zone II grade stipulated % of sand passed through filter | MSand |

|---|---|---|

| 4.75 mm | 90 - 100 | 99.5 |

| 2.36 mm | 75 - 100 | 83.10 |

| 1.18 mm | 55 - 90 | 55.30 |

| 600 micron | 35 - 59 | 45.80 |

| 300 micron | 8 - 30 | 23.60 |

| 150 micron | 0 - 10 | 4.90 |

*4.75mm, 2.36mm, 1.18mm, 600 micron, 300 micron, 150 micron particles are present in Poabs MSand as stipulated by IS 383(1970) zone II grade.

Cleaning – The particle below 1.18 mm is perfectly graded with help of dry cycle Air Classifier to control the microfines below 150 microns to less than 10% in Original MSand without losing the smaller grade particles in sand.

Quality control – Poabs has an experience of 29 years in crushing and 12 years in manufacturing of MSand. The quality control of MSand is monitored by Government College of Engineering, Thiruvananthapuram.

Trade mark – MSand is the registered trademark of Poabs. Only Poabs has the right to use this trademark. Using this trademark by others will be liable to prosecution.

Bills – Ask for the bill of Original MSand. If you are not getting the bill with correct date and amount then the product is likely to be the duplicate.

Call Poabs – If you have any doubts regarding Poabs or if you have been duped by duplicates, please contact Poabs.

Benefits to the consumers

Strength and long lastingOnly Original MSand can give you strong and long lasting concrete for construction

Low expenseOriginal MSand gives the concrete strength and durability if used in the right amount with cement. This lowers the expense of construction.

100% profitMSand comes in two different grades for concreting and plastering. So there is no loss of sand during masonry works due to sieving.

Comparison between M-Sand and Crusher Dust

| Sl No: | M-Sand | Crusher Dust |

|---|---|---|

| 01. Colour | Grey | Grey |

| 02. Particle Shape | Cubically Shaped | Flaky |

| 03. Product | Manufactured as per IS, BS, ASTM Standards | Elongated (Shapeless) a) It is fractured dust of jaw crusher b) A waste product in production process of stone crusher |

| 04. Manufacturing Process | Internation technology controlled manufacturing process through imported machines | No controlled manufacturing process as it is the by-product of stone crusher |

| 05. Gradation | As per IS 383 - 1970 Zone-II |

Does not adhere to IS 383 - 1970 or any other standards |

| 06. Suitability for concreting | Recommended for usage in concrete & masonry works worldwide by the concrete technologists. Confirms international standards | Not recommended for use in concrete or masonry works. Does not have quality. |

The superior shape, proper gradation of fines, smooth surface texture and consistency in production parameter of chemically stable sands provide greater durability and higher strength to concrete by overcoming the deficiencies like segregation, bleeding, honey combing, voids and capillary.

Greater workabilityThe crusher dust is flaky and angular in shape which is troublesome in working. There is no plasticity in the mortar which makes yet difficult for the mason to work. Where as the cubical shape with grounded edge and superior gradation gives good plasticity to mortar providing excellent workability.

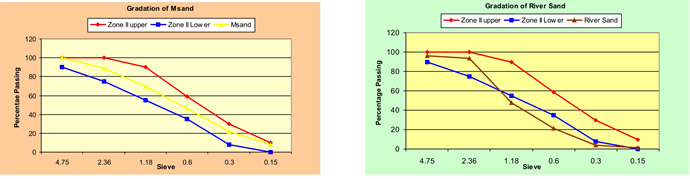

Comparison between River Sand Vs M-Sand

| SIEVE ANALYSIS | River Sand Vs M-Sand | ||

|---|---|---|---|

| IS SIEVE | RIVER SAND % Age Passing |

M-SAND % Age Passing |

% Age passing for single sized aggregates of Normal Sand (IS 383 - 1970) Zone II |

| 4.75 mm | 99.25 | 99.75 | 90 to 100 |

| 2.36 mm | 93.50 | 78.25 | 75 to 100 |

| 1.18 mm | 48.00 | 52.00 | 55 to 90 |

| 600 Microns | 21.00 | 38.00 | 35 to 59 |

| 300 Microns | 04.00 | 21.00 | 08 to 30 |

| 150 Microns | 0.05 | 5.00 | 0 to 10 |

| Comparison of Impurities - River Sand Vs M-Sand | |||

|---|---|---|---|

| RIVER SAND | M-SAND | ||

| Marine Products | 2 - 4 % | Nil | |

| Oversized Materials | 6 - 10 % | Nil | |

| Clay & Silt | 5 - 20 % | Nil | |